Product number: ZYT021363

Back to page

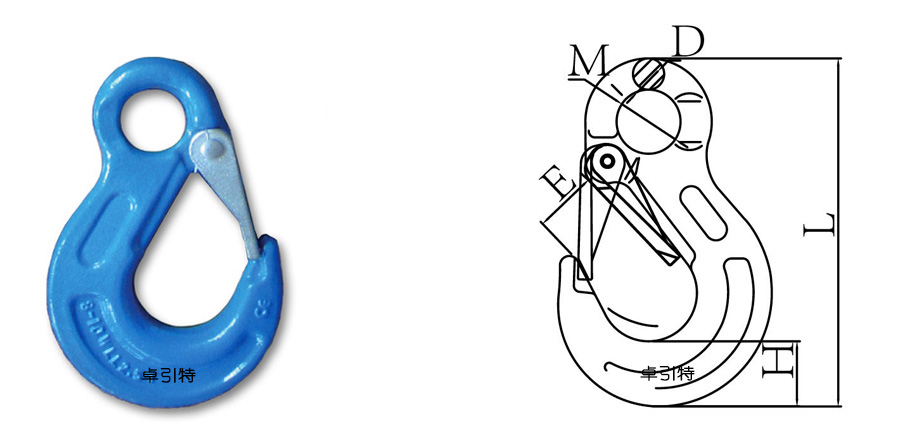

G80 eye sling hook

●Forged super alloy steel-Quenched and tempered

●Individually proof test at 2.5 times working load limit.

●Fatiuge tested for 20000 cycles.

●Breakage test

●100% magnaflux crack detection.

●With cast latch

●Suitable for EN818-2 G80 chain.

●Safety factor 4:1

●Surface finish: Powder plastified.

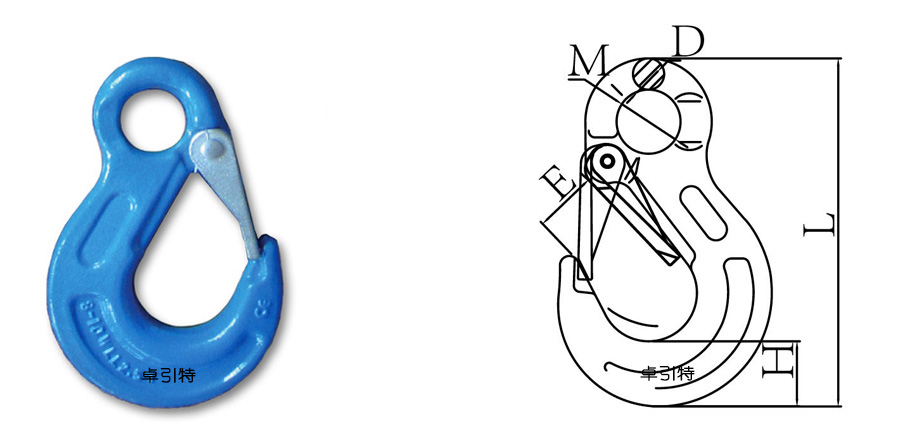

G100 Eye Sling Hook

●Forged super alloy steel-Quenched and tempered.

●25% stronger than G80.

●Individually proof test at 2.5 times working load limit.

●Fatiuge tested for 20000 cycles.

●Breakage test

●100% magnaflux crack detection.

●With cast latch

●Suitable for G100 chain.

●Safety factor 4:1

●Surface finish: Powder plastified.

●Individually proof test at 2.5 times working load limit.

●Fatiuge tested for 20000 cycles.

●Breakage test

●100% magnaflux crack detection.

●With cast latch

●Suitable for EN818-2 G80 chain.

●Safety factor 4:1

●Surface finish: Powder plastified.

| ITEM NO. | WLL | Breaking Strength | Size(mm) | Weight | ||||

| T | T | B±1 | E±1 | A±1 | L±1 | H±1 | kg | |

| 8-013-06 | 1.12 | 4.48 | 9 | 24 | 20 | 108 | 21 | 0.3 |

| 8-013-7/8 | 2 | 8 | 11 | 30 | 25 | 133 | 27.5 | 0.4 |

| 8-013-10 | 3.15 | 12.6 | 15 | 34 | 38 | 167 | 33 | 0.9 |

| 8-013-13 | 5.3 | 21.2 | 19 | 39 | 43 | 213 | 43.5 | 1.7 |

| 8-013-16 | 8 | 32 | 23 | 46 | 50 | 255 | 50 | 3.2 |

| 8-013-20 | 12.5 | 50 | 24 | 48 | 56 | 305 | 56 | 5.8 |

| 8-013-22 | 15 | 60 | 32 | 71 | 62 | 348 | 62 | 8.5 |

| 8-013-26 | 21.2 | 84.8 | 35 | 81 | 74 | 394 | 75 | 13 |

| 8-013-32 | 31.5 | 126 | 37 | 102 | 88 | 480 | 89 | 17 |

G100 Eye Sling Hook

●Forged super alloy steel-Quenched and tempered.

●25% stronger than G80.

●Individually proof test at 2.5 times working load limit.

●Fatiuge tested for 20000 cycles.

●Breakage test

●100% magnaflux crack detection.

●With cast latch

●Suitable for G100 chain.

●Safety factor 4:1

●Surface finish: Powder plastified.

| ITEM NO. | WLL | Breaking Strength | Size(mm) | Weight | ||||

| T | T | D±1 | E±1 | H±1 | M±1 | L±1 | kg | |

| 10-1003-06 | 1.4 | 5.6 | 10 | 18.5 | 21 | 20.5 | 111 | 0.32 |

| 10-1003-08 | 2.5 | 10 | 11 | 25 | 27.5 | 25 | 137.5 | 0.6 |

| 10-1003-10 | 4 | 16 | 16 | 28 | 33 | 34 | 171.5 | 1.2 |

| 10-1003-13 | 6.7 | 26.8 | 19 | 38 | 43.5 | 43 | 219 | 2.2 |

| 10-1003-16 | 10 | 40 | 24.5 | 44 | 50 | 50 | 260 | 3.5 |

| 10-1003-20 | 16 | 64 | 27 | 52 | 56 | 56 | 298 | 7.15 |

| 10-1003-22 | 19 | 76 | 29 | 66 | 62 | 62 | 330 | 11.5 |

| 10-1003-26 | 26.5 | 106 | 35 | 73 | 75 | 75 | 376 | 12.2 |

| 10-1003-32 | 39.3 | 157.2 | 39 | 87 | 89 | 89 | 458 | 17.5 |

Application scenarios

PDF file download