Product number: ZYT021369

Back to page

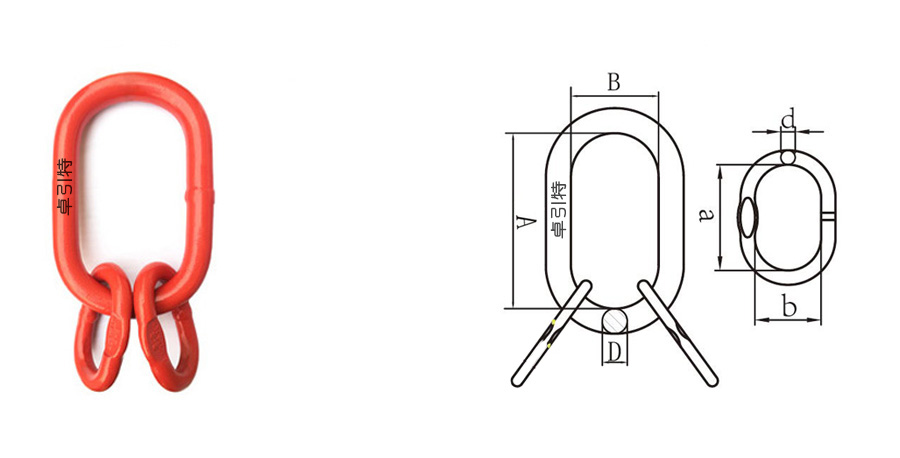

Master link assembly

●Standard :EN1677-4.

●Forged super alloy steel-Quenched and tempered

●Individually proof test at 2.5 times working load limit.

●Fatiuge tested for 20000 cycles.

●Breakage test

●100% magnaflux crack detection.

●WLL based on 0-45° for 3 or 4 legs G80 chain sling.

●Suitable for 3 or 4 legs G80 chain sling as per EN818-4

●For use with wire rope sling,refer to DIN3088 standard.

●For use with synthetic sling,refer to EN1492-1 standard.

●Safety factor 4:1

●Surface finish: Powder plastified.

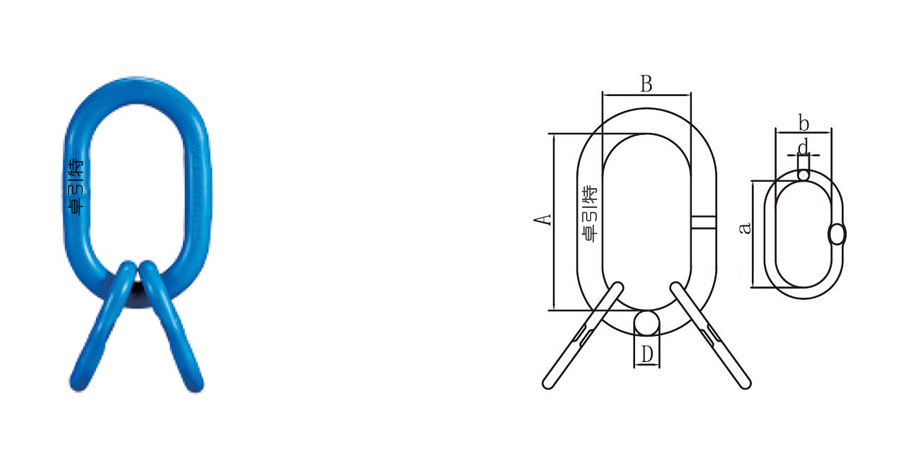

G100 Master Link Assembly

●Forged super alloy steel-Quenched and tempered

●25% stronger than G80.

●Individually proof test at 2.5 times working load limit.

●Fatiuge tested for 20000 cycles.

●Breakage test

●100% magnaflux crack detection.

●Safety factor 4:1

●Surface finish: Powder plastified.

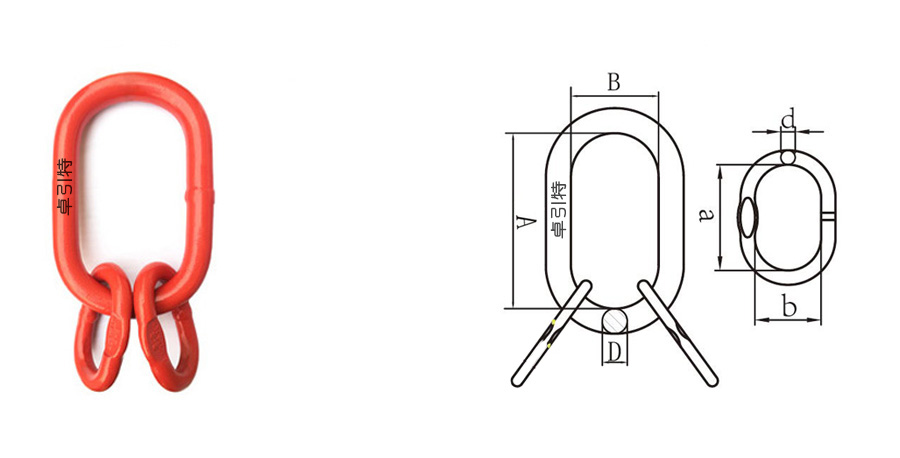

●Forged super alloy steel-Quenched and tempered

●Individually proof test at 2.5 times working load limit.

●Fatiuge tested for 20000 cycles.

●Breakage test

●100% magnaflux crack detection.

●WLL based on 0-45° for 3 or 4 legs G80 chain sling.

●Suitable for 3 or 4 legs G80 chain sling as per EN818-4

●For use with wire rope sling,refer to DIN3088 standard.

●For use with synthetic sling,refer to EN1492-1 standard.

●Safety factor 4:1

●Surface finish: Powder plastified.

| ITEM No. | WLL | Breaking Strength | Size(mm) | Weight | |||||

| T | T | A | B | D | a | b | d | kg | |

| 8-032-06 | 2.36 | 9.44 | 135 | 75 | 18 | 54 | 25 | 13 | 1.18 |

| 8-032-08 | 4.25 | 17 | 160 | 90 | 22 | 70 | 34 | 16 | 2.2 |

| 8-032-10 | 6.7 | 26.8 | 180 | 100 | 26 | 85 | 40 | 18 | 3.4 |

| 8-032-13 | 11.2 | 44.8 | 200 | 110 | 32 | 115 | 50 | 22 | 6.1 |

| 8-032-16 | 17 | 68 | 260 | 140 | 36 | 140 | 65 | 26 | 9.98 |

| 8-032-18 | 21.2 | 84.8 | 340 | 180 | 45 | 180 | 100 | 32 | 18.9 |

| 8-032-20 | 26.5 | 106 | 350 | 190 | 50 | 180 | 100 | 32 | 22.6 |

| 8-032-22 | 31.5 | 126 | 350 | 190 | 50 | 180 | 100 | 36 | 25.2 |

| 8-032-26 | 45 | 180 | 400 | 200 | 56 | 180 | 100 | 40 | 35.2 |

| 8-032-32 | 63 | 252 | 460 | 250 | 72 | 200 | 110 | 50 | 66.46 |

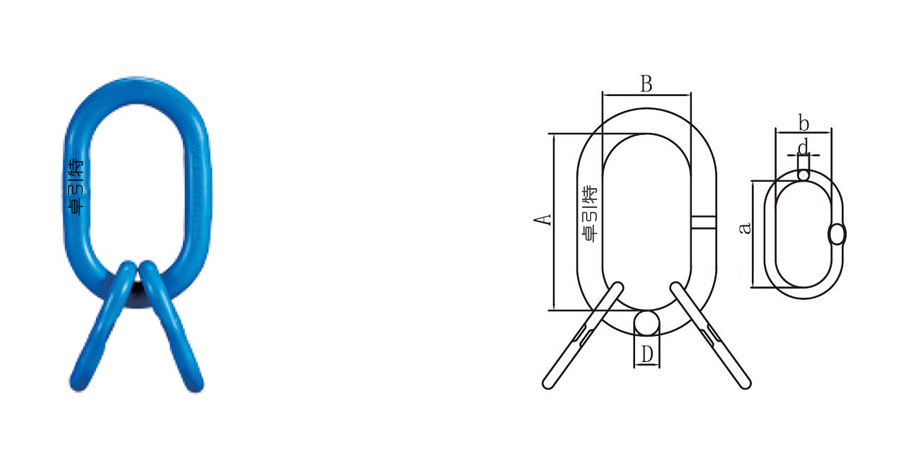

G100 Master Link Assembly

●Forged super alloy steel-Quenched and tempered

●25% stronger than G80.

●Individually proof test at 2.5 times working load limit.

●Fatiuge tested for 20000 cycles.

●Breakage test

●100% magnaflux crack detection.

●Safety factor 4:1

●Surface finish: Powder plastified.

| ITEM No. | WLL | Breaking Strength | Size(mm) | Weight | |||||

| T | T | A | B | D | a | b | d | kg | |

| 10-1012-06 | 3 | 12 | 135 | 75 | 19 | 54 | 25 | 13 | 1.3 |

| 10-1012-08 | 5.3 | 21.2 | 160 | 90 | 23 | 70 | 35 | 16.5 | 2.33 |

| 10-1012-10 | 8 | 32 | 180 | 100 | 27 | 85 | 40 | 19 | 3.7 |

| 10-1012-13 | 14 | 56 | 200 | 110 | 33 | 115 | 50 | 23 | 6.5 |

| 10-1012-16 | 21.2 | 84.8 | 260 | 140 | 36 | 140 | 65 | 27 | 10.1 |

| 10-1012-20 | 33.6 | 134.4 | 350 | 190 | 50 | 150 | 70 | 33 | 22.8 |

| 10-1012-22 | 33.9 | 135.6 | 350 | 190 | 50 | 180 | 100 | 36 | 26 |

Application scenarios

PDF file download