返回上一页

ESB型不锈钢手动绞盘

Electropolishing: A lustrous film is formed on the stainless steel surface by an electrolysis.

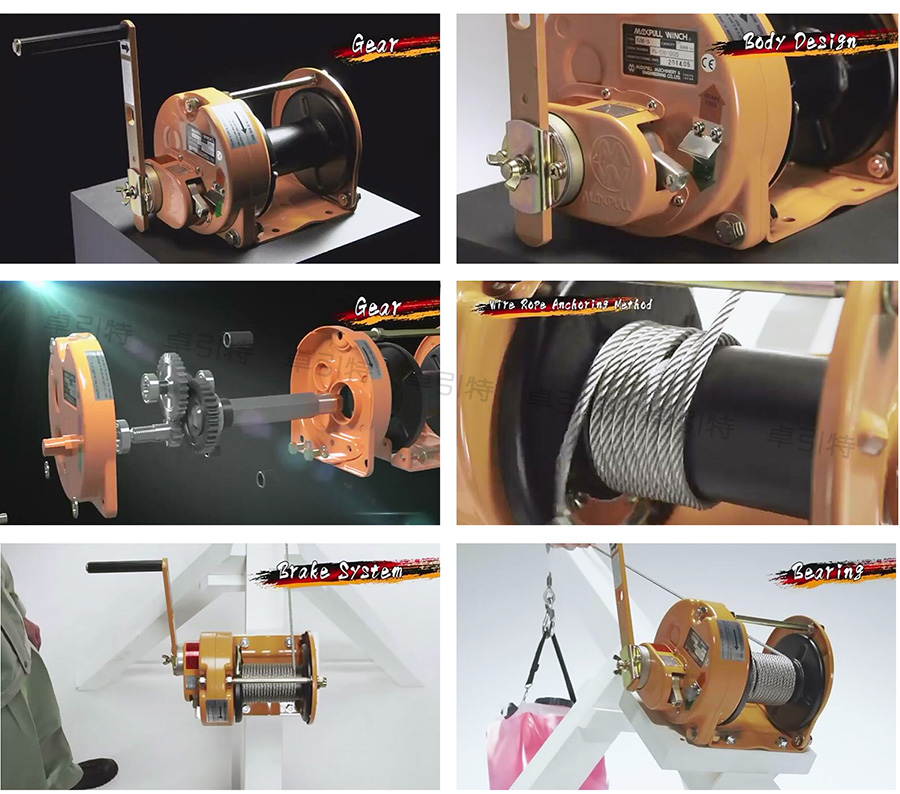

Ease of operation

Ease of operationIf you compare our product with others, the handle force during operation is very small and work is easy because of its high-level mechanical efficiency. This winch is light and very convenient to carry for the compact design. Users can install the winch easily using the prescribed bolts. In addition, each part is made by press work and the whole of winch is assembled with bolts, so it is easily disassembled. Anyone can repair and assemble this winch by just purchasing necessary replacing parts and installing them according to the instructions in the manual.

Outstanding durability

Outstanding durabilityBall bearings (Stainless steel) only from leading manufacturers are used for all bearings. The bearing allows smooth lifting and offers outstanding resistance against wear. Our unique profile shifted gear that performed special heat treatment is used for the gear reducer, and it allow you to work securely. The automatic brake has outstanding durability because it has the mechanism that can adjust the gap as desired. Baking finish performed on the surface is resistant to rust. It is strong and can be used in any location.

Reliable safety

Reliable safetyCarefully selected materials as well as advanced design and technology provide the extremely high safety. We have enhanced the strength of the portions where load is intensively applied by combining a precision press-processing rib or double plate. A fail-safe mechanism is employed for the mechanical brake, so it never enters the state of no brake even if the impact is applied to a stopper arm. The method of anchoring the wire rope to the drums is a fail-safe structure with a special drum that an extra maintenance winding is maintained. Users can easily and surely anchor the end of a wire rope to the drum by using the attached hex wrench. The above features are all enabled thanks to our unique reliable safety design.

| Model | ESB-1 | ESB-3 | ESB-5 | ESB-10 |

| Max capacity | 980N (100kgf) 5φ Winding of a wire rope up to 4th layer | 2940N (300kgf) 6φ Winding of a wire rope up to 5th layer | 4900N (500kgf) 6φ Winding of a wire rope up to 5th layer | 9800N (1000kgf) 8φ Winding of a wire rope up to 3rd layer |

| Drum capacity | φ5X35m | φ6X32m | φ6X40m | φ8X40m |

| Gear ratio | 1/1 | 1/6.25 | 1/8.9 | 1/12.6 |

| Handle force 1 | 1st layer : 143N (14.6kgf) | 1st layer : 76N (7.7kgf) | 1st layer : 109N (11.1kgf) | 1st layer : 133N (13.5kgf) |

| Handle force 2 | 3rd layer : 187N (19.0kgf) | 3rd layer : 103N (10.5kgf) | 3rd layer : 142N (14.4kgf) | 2nd layer : 157N (16.0kgf) |

| Handle force 3 | 4th layer : 208N (21.2kgf) | 5th layer : 131N (13.3kgf) | 5th layer : 174N (17.7kgf) | 3rd layer : 182N (18.5kgf) |

| Handle length | 250mm | 250mm | 250mm | 300mm |

| Weight | 7.4 kg | 14.3 kg | 15.6 kg | 16.6 kg |

应用场景

PDF文件下载

你的需求

需求与招标计划? 请告诉我们!

> 在线填写表单